TYRE PRESSURE MONITORING SYSTEM

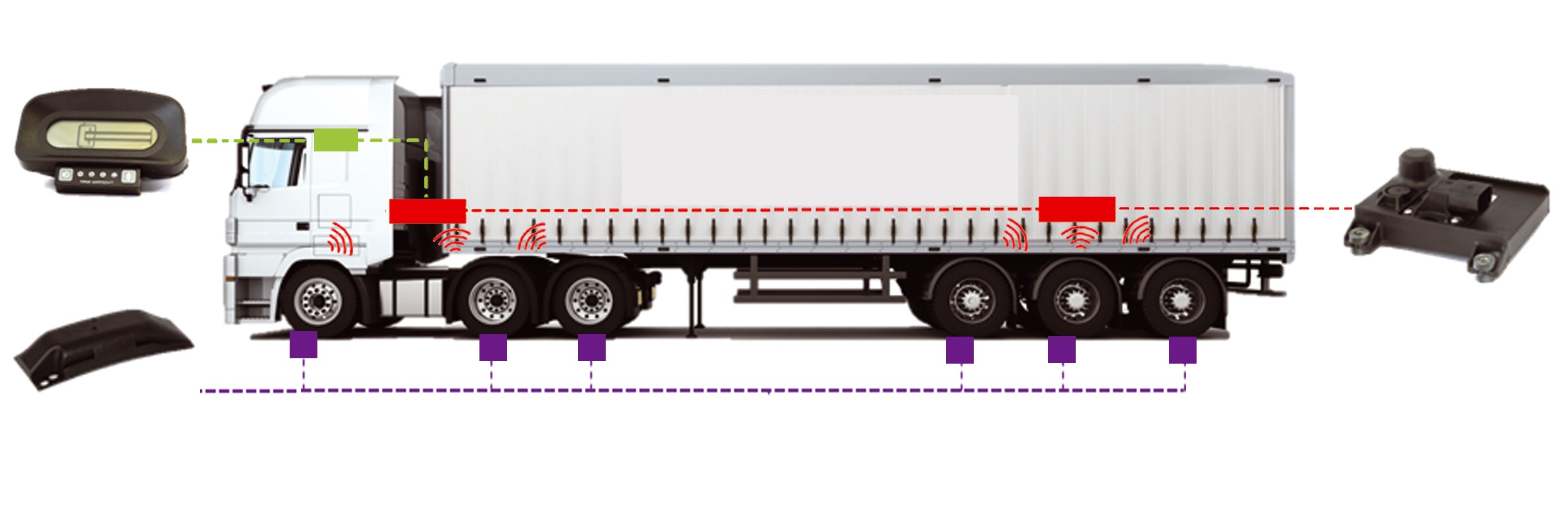

TPMS systems measure the pressure in individual tyres, using sensors mounted on the wheel rim, on the inside of the tyre and can be applied to all types of LCVs and HDVs. TPMS system detects under-inflation in each tire by monitoring tyre pressure and temperature inside the tire. As a standard function of our TPMS an air temperature measurement of each tire is available and visible in cockpit or/and monitoring platform.

TPMS has the advantage of determining absolute pressure values, low risk of (un)intentional misuse and high accuracy and advantage of 5 years lifetime of sensor batteries.

Based on an review of current products and suppliers it can be concluded that TPMS for application in LCVs and HDVs are a technically and economically mature product. Expected future developments are mainly directed at improved performance. TPMS increases functionality by connecting vehicle TPMS information to fleet management systems.

Main advantages of implementing TMPS are

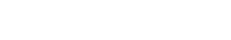

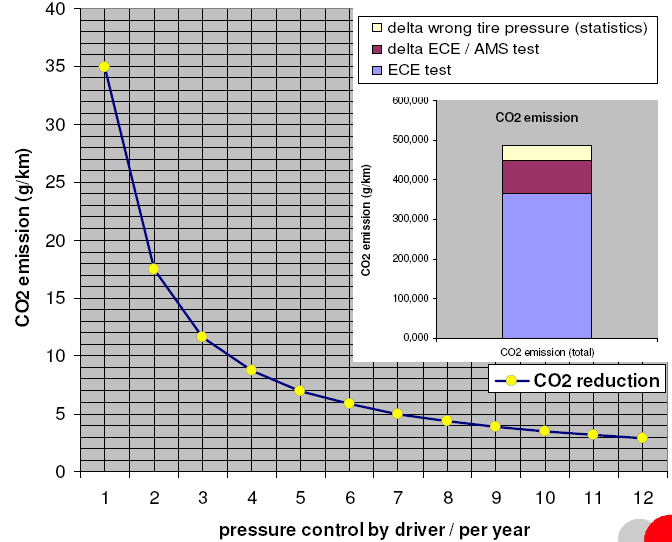

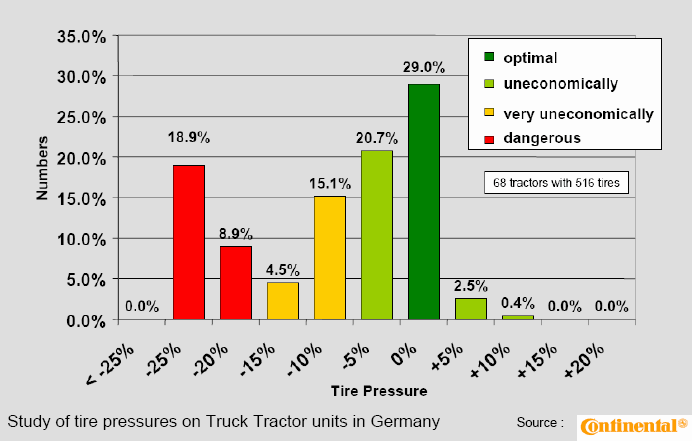

- Fuel consumption reduction: up to 15%

- Increasing tire lifetime: up to 30%

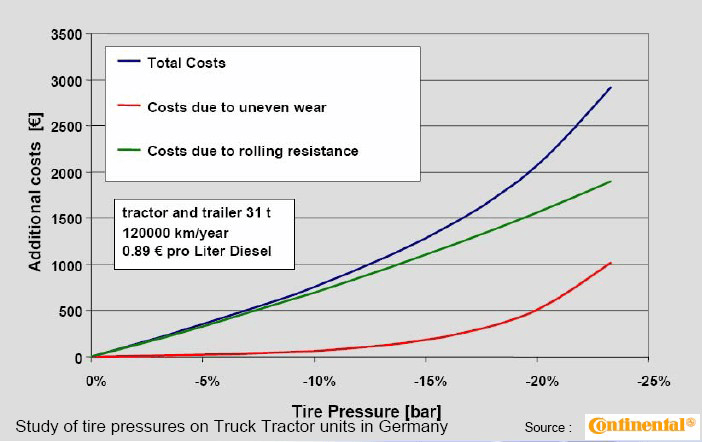

- CO2 emissions reduction.

TPMS Specifications:

- Up to 24 tire sensors supported (one receiver);

- In case of a second receiver additional 12 tire sensors must be connected;

- Cockpit display – with automated illumination and build in memory for 24 messages;

- GPS tracker, connected to TPMS equipment;

- System power supply: 12 – 36 VDC;

- Sensors tire supply: 3 VDC;

- Connection line (tire sensors – receiver): wireless – 434 MHz;

- Connection line (GPS tracker – TPMS receiver) – RS-232 over CAN-BUS J1993 protocol;

- Data timeout (sensors – receiver): 0,01 second;

- Data timeout (GPRS GPS receiver: up 25 seconds)

- Sound and Light activation in case of an alarm message;