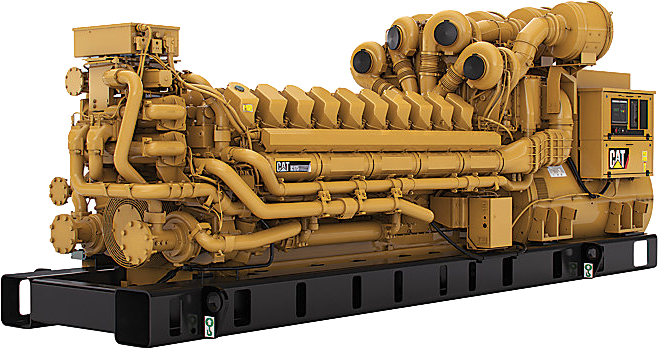

Diesel Generators

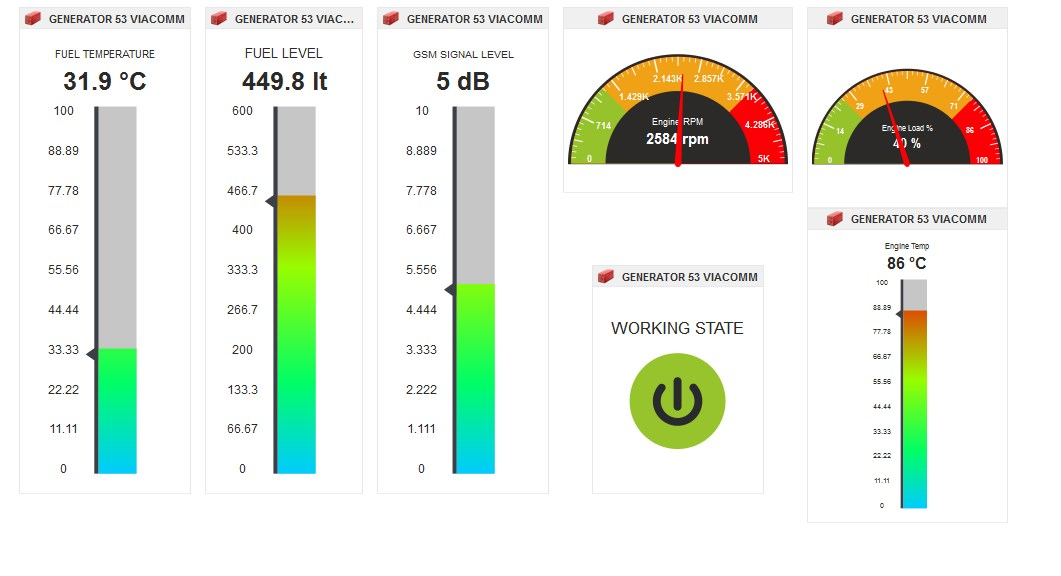

Our daily work and experience with the platform has provided to us a new services – a special diesel generators monitoring application has been launched. Having the experience to operate and read out different signals from different types of sensors, our engineers have added a new value to our service: Monitoring and control of parameters of diesel generators and alarm states.

- Diesel Generator statistics;

- Generator Engine Hours;

- Fuel Used in engine hours;

- Fuel Filled – amount;

- Date Time and amount of fuel filling(s);

- Fuel Stolen – amount;

- Date Time and amount of fuel theft;

- Detailed statistics for generator working hours, i.e. start, end, duration, fuel used, etc.;

- Graphic chart fuel level;

- Graphic chart fuel temperature;

- Graphic chart generator accumulator;

GSM signal level graphic chart of place of working.

For easy and comfortable operation and serving, special notifications are generated. Special notifications for the generator maintenance status are available:

- Notification: Critical Fuel Level (adjustable);

- Notification: High Temperature;

- Notification: No power supply (grid 220 VAC);

- Notification: Generator has been started;

- Notification: Generator is not connected to the grid;

- Notification: Generator’s power supply is connected to the grin;

- Notification: Main grid power supply is off from the Generator’s power supply;

- Notification: Generator is stopped (when the main grid power supply is available);

- Notification: Main grid power supply is available;

- Notification: Generator is on stand by and ready for next start;

- Notification: GSM signal is missing.

All notifications can be delivered to the staff on-line, via e-mail or SMS.

For the correct and regular maintenance a special module – Service Intervals is available.

Service Intervals module can observe the following events and conditions:

- Change of oil and oil filter of generator (by engine hours or calendar);

- Change of fuel filter of generator (by engine hours or calendar);

- Change of air filter of generator (by engine hours or calendar);

- Change of oil transmission of generator (by engine hours or calendar);

- Maintenance and spare parts management, including cost of the maintenance;

- Service engineer who did the maintenance and date of next maintenance;

The constant improvement of our service and working environment allows to all our customers to have better visualization, maximum flexibility and user friendly screens.

The new monitoring panel keeps also and alarm functionalities! Sounds and visual alarms are available!